Microelectromechanical Systems

Abstract: In this project we aim to work on the design and fabrication of various MEMS devices. As a part of our project we, in particular, investigated a micromachined-gas sensor. The reliability of the membrane structure for micromachined-gas sensors is one of the main concerns in MEMS technology. The major source of this problem is the stress on the membrane. We found that the use of SiO2/Si3N4/SiO2 stacked layers with optimized dimensions reduces the stress on the membrane, and hence improves the reliability. We also use electro-thermal simulations with finite element analysis (FEA) to model the structural properties of the membrane in order to reduce the stress. The appropriate selection of materials and dimensions yields maximum active area temperature of 530 degrees C at the center of the membrane with a polysilicon heater element, less than 5 V supply voltage, 40 mW of power consumption, membrane edge temperature of 177 degrees C and acceptable mechanical stress of 0.097 GPa. Upon realizing the structure with the modeled parameters, micromachined-gas sensors could respond to many industry/environment application demands.

Keywords: Microelectromechanical Sytems, Gas Sensors

Collaborators: Yasar Gurbuz (Sabanci University, Turkey), Ayhan Bozkurt (Sabanci University)

Due to society's concern with the environment and the industry's need for operating under ever more demanding conditions, the necessity of gas sensors to detect, monitor, and control various chemical species with a better sensitivity, selectivity, reproducibility and rapid response at reasonable cost becomes more obvious. Among others, semiconductor type gas sensors have been used for several decades [1]. They rely on the interactions between certain ambient species and the active portion of the sensing device. The magnitude of the change is mostly related to the concentration and type of gas components, structural properties of the sensing device and operating temperature. Due to the improved sensing performance of these sensors, high temperature operation and compatibility are greatly desirable in many applications (such as automotive, environment, process control, etc). They are fabricated using IC manufacturing technologies, providing a smaller size and lower weight, lower power consumption, and lower cost due to the automated and batch production. However, these type of sensors still lack of sensitivity, selectivity, and speed, preventing the extended use in markets such as health care, environment, process control, agriculture, etc. A couple of research groups have successfully addressed the sensitivity and selectivity issues by using high temperature tolerant semiconductors (e.g., diamond, SiC) in conjunction with gas sensitive electrodes [2-5]. These sensors have been demonstrated to meet the required ppm-level of sensitivity, milliseconds of response time and selectivity for hydrocarbons and other gases up to 600 degrees C of operation. These performance parameters are better than those of their conventional counterparts (i.e., Si- or GaAs-based), demonstrated to date.

During the last two decades, largely two-dimensional IC fabrication technology has been extended into the third dimension by micromachining technologies-- a combination of special etchants, etch stops, and sacrificial layers. Micromachining has been used to produce a growing variety of micromechanical structures, including automotive pressure sensors, airbag deployment accelerometers and many others [6-8]. Given the similarities between IC fabrication and micromachining, microelectronics and micromechanics may be integrated on a single chip, allowing on-chip monitoring and control of the mechanical/chemical functions. This has led to the term microelectromechanical systems (MEMS) to describe this technology. The use of micromachining could provide a number of opportunities for gas sensors: the sensing elements can be miniaturized (reducing power consumption), multiple elements can be integrated into array configurations with each element optimized to sense a different gas, improved selectivity/sensitivity and the integration of sensing and signal processing/control devices on the same substrate. In addition, due to the small mass of the micromachined-sensor element, rapid thermal programming can be employed to introduce a level of kinetic selectivity into the operation of the sensor.

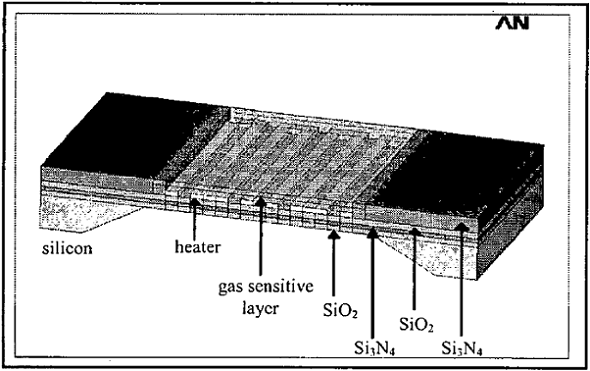

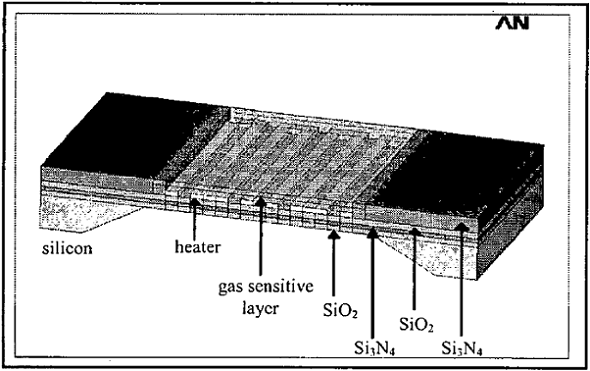

Recent research activities in the field of solid-state gas sensors have been directed toward the combination of thin film technologies for the deposition and/patterning of the sensitive materials and micromachining technologies for the fabrication of thermally isolated devices [9-11]. For low power consumption and good thermal isolation from the surrounding IC circuitry, the sensor structure has to be mounted on a membrane/bridge that comprise supporting layers, a heater and sensor electrodes and gas sensitive layers. This membrane structure provides the thermal isolation between the active area, generally heated to 250-500 degrees C, and the outer signal processing/control circuitry. The temperature on the periphery of the membrane should remain below 200 degrees C due to its intimate contact with neighboring Si-based ICs. Other major concerns for the design of micromachined-gas sensors is the mechanical stress, caused by the thermal cycling of the microheater on the membrane, and power consumption.

As a part of our MEMS project we started with micromachined gas sensors described above (Fig. 1). We have performed the simulation of electro-thermal characteristics and modeling of intrinsic and thermal induced mechanical stress at the membrane of the micromachined-gas sensors. In this project we mainly use ANSYS [12] for finite element analysis to control mechanical stress and power consumption and also numerical calculations of the membrane and heater materials.

Figure 1 Schematic of a typical micromachined gas sensor.

We have utilized a stacked membrane consisting of SiO2/Si3N4/SiO2 to reduce the stress and prevent the deformation and breaking. In our FEA simulations we achieved to obtain maximum active area temperature of 530 degrees C at the center of the membrane, with a polysilicon as a heater element, less than 5V supply voltage, 40mW of power consumption, membrane edge temperature of 177 degrees C, and an acceptable mechanical stress of 0.097GPa. Upon realization of a micromachined-gas sensor with these parameters, a better sensing and reliable performance, wide application range, lower cost and longer lifetime could be expected.

In this project we collaborate with Microelectronics Group, in Sabanci University, Turkey.

References

[1] N. Taguchi, Gas detecting devices, U.S. Patent 3,631.436 (1971).

[2] A. Arbab, A. Spetz, Q. U. Wahab, M. Willander, and I. Lunstrom, Chemical sensors for high temperatures based on silicon carbide, Sensors Mater. 4, 173 (1993).

[3] W. P. Kang, Y. Gurbuz, J. L. Davidson, and D. V. Kerns, A new hydrogen sensor using a polycrystalline diamond-based schotkky diode, J. Electrochemical Soc. 141, 2231 (1994).

[4] Y. Gurbuz, W. P. Kang, J. L. Davidson, D. V. Kerns, Analysis of current conduction mechanism and gas adsorption effects on device parameters of diamond based oxygen gas sensors, IEEE Transactions on Electron Devices 46, 914 (1999).

[5] A. Baranzahi, A. L. Spetz, R. Johansson, G. Hamrefors, and I. Lunstrom, Influence of the interaction between molecules on the response of a metal-oxide silicon carbide, Eurosensor IX, June 24-29, 1995 Stockholm, Sweden.

[6] Y. S. Lee and K. D. Wise, A batch-fabricated silicon capacitive pressure transducers with low temperature sensitivity, IEEE Transactions on Electron Devices ED-29, 42 (1982).

[7] http://www.analog.com/imems

[8] An SPC Market Study -Jan 1999, Microelectromechanical Systems (MEMS): Emerging Applications and Markets (Mr. Bill Detlefs, System Planning Corporation)

[9] S. Semancik and R. E. Cavicchi, The use of surface and thin film science in the development of advanced gas sensors, Applied Surface Science 70/71, 337 (1993).

[10] C. Hagleitner, A. Scaufelbuhl, O. Brand, H. Baltes, C. Menolfi, and Q. Huang, Micromachined CMOS calorimetric chemical sensor with on-chip low noise amplifier, Proc. IEEE Workshop on Micro Electro Mechanical Systems MEMS 99, Orlando 1999.

[11] L.-Y. Sheng, Z. Tang, J. Wu, P. C. H. Chan, J. K, O. Sin, A low noise CMOS compatible integrated gas sensor using maskless tin oxide sputtering, Sensors and Actuators B 49, 81 (1998).

[12] ANSYS is aregistered trademark of Swanson Analysis Systems Inc.